A patented detection system that prevents corrosion and monitors leaks underneath insulation at an early stage.

Very flexible system that is delivered and built modular like «Lego bricks»

Both offshore and land-based industries are facing severe challenges regarding corosion under the insulation that protects the pipes.

A common denominator for most of these industries is that the pipes often carry harmful substances.

Corosion and damages of the pipes are hidden under the insulation.

A leak under the insulation may increase over time, causing big and expensive consequences. The substances leak, and can wander along the pipes underneath the insulation. In many cases, this can be hard to locate, which means unnecessary removal of big areas of insulation trying to locate the source of the leak.

Prosence has developed a patented detection system(PDS) that prevents corrosion and monitors leaks underneath insulation at an early stage.

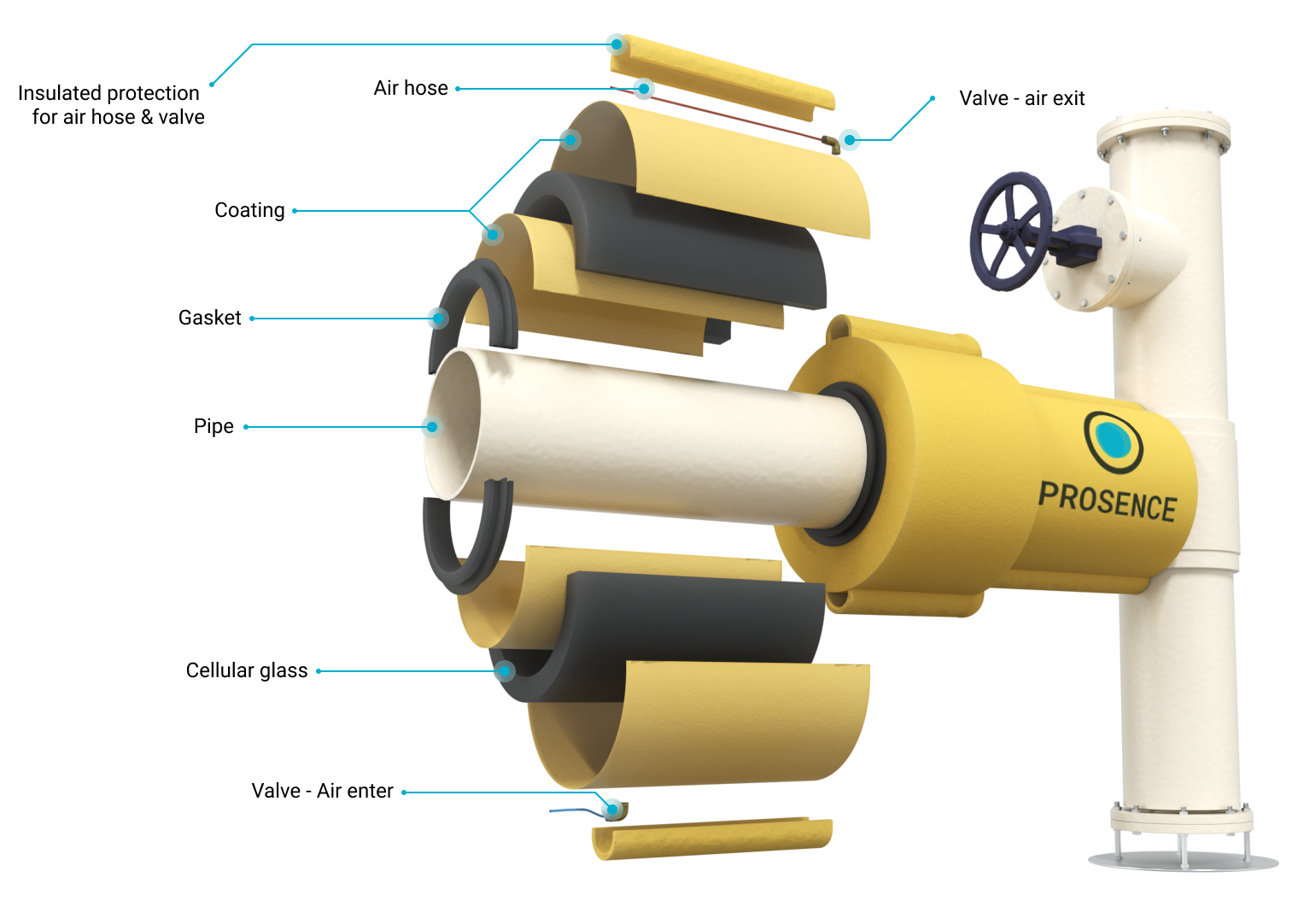

PDS consists of a detection cabinet and controlled air pockets(CAP).

One CAP contains an airtight pocket located between the pipe and the insulation. This barrier protects against external damages and substances which can provoke the process of corrosion.

Air is added, circulates inside the chamber and then exits via a pair of valves, repeatedly sending back information to the control cabinet, where necessary measurements are made.

Controlling the air between the insulation and the pipe minimizes the chance of corrosion.

Measurements are made on potential leaks, humidity, pressure, and temperature. Each section(CAP) is delimited by gaskets which enables the sections to be inspected individually, thus gaining full control over the condition status for each section.

A gas leak will easily be detected using this system.

The CAP shields the pipes from exposure to external moisture.

In the event of a leak or an injured CAP, the system will detect and pinpoint the injured CAP, which easily can be removed, restored, reused or replaced.

Prosence offers an efficient monitoring system that provides eyes on the inside of the CAP. This reduces unnecessary maintenance, lessens downtime, and leads to significant advantages both economical and environmental.

PDS aims to contribute to the world’s goals for a sustainable development.

PDS eliminates corrosion under insulation

PDS prevents and detects leaks in real time

PDS provides lower energy consumption, with an associated positive environmental effect

Very flexible system that is delivered and built modular like «Lego bricks»

Short installation time on new and existing installations.

For all types of pipe dimensions and lengths.

Avoid accidents and leaks.

Provides lower energy consumption.

Less replacement of equipment.

Minimize unnecessary downtime.

Eliminate manual inspections.

Automatic control 24/7 via monitoring system

Ensures a longer service life for pipes, valves and insulation.

PDS measures temperatures throughout the life of the insulation and will give the owner of the system the opportunity to predict maintenance and replacement of insulation. This will cause the insulation to be replaced when it has deteriorated - and not before, and provide a more stable operation due to the medium in the pipe having an even temperature.

According to the report from the European Industrial Insulation Foundation, (commissioned by the EU), there are major environmental and economic benefits to improving the insulation effect.

PDS has properties that can prevent major accidents with the potential for environmental disasters.

Where PDS is installed, fugitive emissions will be detected immediately.

Excerpt from report from European Industrial Insulation Foundation.